|

Anhui YiBang New Material Technology Co., Ltd

|

Gold Index: 255998

| Price: | 5.0~10.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. It becomes rigid again when cooled. This temperature behavior is exploited for extrusion, and also for molding and vacuum forming, since it can be cast into molds with fine detail.

The proper way to transport and store polystyrene is through FIBCs/bulk bags

Why choose FIBCs/bulk bags

1.FIBCs have the lowest package to product weight ratio of any intermediate industrial container. Ship one metric ton of product with a package weight as little as 5-7 lbs (2-3 Kg)

2.Can be handled, transported and stored without pallets due to integrated lifting loops

3.When empty they are lightweight and can fold flat to take up a fraction of the space required for other industrial packages

4.Can be customized to meet your needs (Size & Capacity,Filling & Discharging Features, Barrier Properties, Handling Features, etc.)

About polystyrene packing bulk bag

Picture of the polystyrene packing bulk bag

(1) Characteristics: Our products with different function like dust-proof, moisture-proof, radiation-resistant, safety, fastness,etc.

(2) It has high strength structure, easy to load and unload.

(3) Can widely used for packing lead zinc ore, copper ore, sandstone, cement, chemical products, grain, ore product and various kinds of powder and granular goods.

(4) Load: 0.5-3T; capacity: 500-2300L

About Ebang Anhui YiBang New Material Technology Co., Ltd is a professional manufacturer of FIBC (Big Bag/Jumbo Bag).We produce an extensive line of Flexible Intermediate Bulk Containers (FIBCs) to meet both large and small volume requirements.Our products can be used for a wide range of solid and ponder products (Chemical, Mineral, Food, Agricultural, etc.)

Our advantage:

1.More than 10 years experience for manufacturing FIBC/ Big Bag

2.We are the direct factory, best price offer

3. We can provide OEM services for buyers

4. Stable productivity,the shortest delivery time

5.Flexible payment terms for old customers.

7.24hours services before and after sales,

make you know clear about the production situation of your order and your container route after shipment.

Manufacture Process of polystyrene packing bulk bag

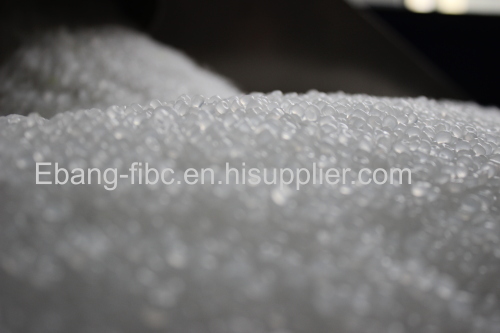

Raw material

We use only 100% virgin PP to make sure that our good quality. I can guarantee that you won't find a single grain of second hand PP in our raw material.

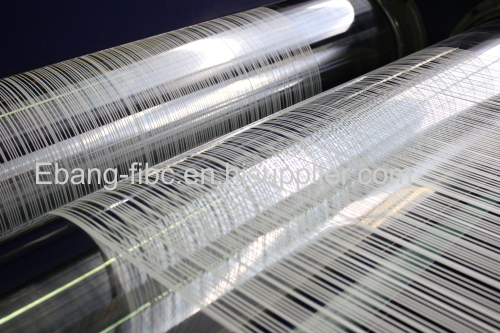

Tape Stretching

From the very basic raw material 100% virgin PP, we make the PP tape through extruding machine and drawing machine. The know-how of the mixture of raw material and our experienced skill in drawing process, we can manufacture the tread with specified strength. And with the special treatment of the raw material , we can add UV or rediation protection function.

Weaving

And skilled workers weave the tape into plastic coth with Circular looms

Cutting

We are also able to print logos or any draft you provide on the surface of the plastic fabrics, then cut the plastic cloth into the specified size.

Sewing

The stitchers then sew the fabrics into one bag.

We can customize various kinds of type and size, such as the following:

90 x90x100cm | 90 x90x160cm | 90 x90x140cm | 90 x90x180cm |

90 x90x120cm | 100 x100x100cm | 100 x100x120cm | 100 x100x140cm |

100 x100x160cm | 100 x100x180cm | 95 x95x140cm | 105 x105x210cm |

DIA110x90cm | DIA110X110cm | 105 x105x135cm | 105 x105x240cm |

Packaging & Delivery

Packaging Detail: | 10bag/package or 20bag/package Regular size: 3000px*750px*500px Bearing capacity: 200packages/20'container ,350packages/40'container |

Delivery Detail: | 15days~25days |